Manufacturing Services

Electronics manufacturing means the complete production processes of electronic devices. It includes PCB fabrication, PCB assembly, electromechanical assembly, testing and inspections, or even electronic design, packaging and distribution. Electronics Manufacturing Services (EMS) providers supply full turnkey electronics manufacturing services to brank owners and original equipment manufacturers (OEMs).

Before discussing the different processes that are involved in electronics manufacturing, it is worth noting to go through the different materials and components that make up an electronic device.

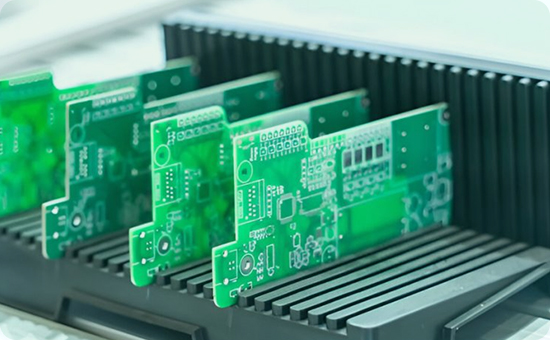

Printed Circuit Board

A printed circuit board (PCB) is one of the major parts in electronics manufacturing. PCB is the base structure that houses the components to connect them physically and electrically. PCBs have become commercially available since the early 1950s. More developments in PCB took place after the World War when consumer products rose in demand. The components of the PCB include a substrate which is a board made of dielectric material and copper conductors that are laminated on the substrate. The copper layer provides the electrical path and the medium for soldering.

A printed circuit board (PCB) is one of the major parts in electronics manufacturing. PCB is the base structure that houses the components to connect them physically and electrically. PCBs have become commercially available since the early 1950s. More developments in PCB took place after the World War when consumer products rose in demand. The components of the PCB include a substrate which is a board made of dielectric material and copper conductors that are laminated on the substrate. The copper layer provides the electrical path and the medium for soldering.

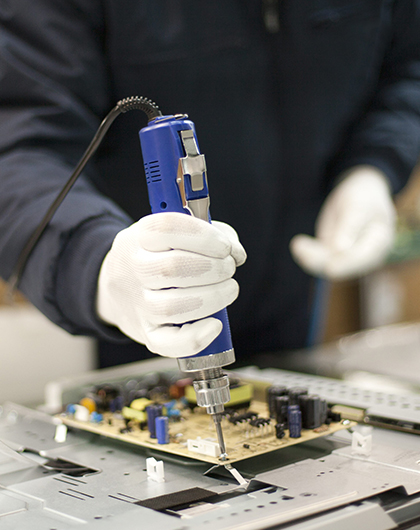

Electronics Manufacturing is a very complex task from PCB fabrication and assembly, to electromechanical assembly, and lots of tests and inspections. Only experienced electronic manufacturers can supply complete Electronics Manufacturing services of high quality. Here we will talk about the basic processes of electronic manufacturing.

Inner layer Fabrication: The image from a virtual artwork is photo plotted on the substrate surface using a photoresist which is exposed to UV light. Etching processes are done to remove the copper pattern that is not part of the circuitry.

Lamination: Multi-layer PCB consists of lamination processes to join the inner layers with a prepreg. A prepreg is a fiberglass material with partially

Drilling: Using reference drill data, holes are drilled on the PCB. The drill sizes are automatically selected and subsequently moved to the drilling positions.

Through Hole Plating: The drilled holes are cleaned to increase adhesion upon copper plating of the holes. Copper plating is done to provide a conductive track on the PCB and through the holes and vias.

Outer Layer Image: In an almost similar manner to the inner layer fabrication, the photoresist film is removed where the copper circuit is intended then again developed and exposed to UV.

Solder Masking: A solder mask must be applied on the PCB substrate to separate the conductive pads and insulating surfaces. Liquid photo imageable solder mask is the most common type in which a photoresist mask is used to generate the pattern through exposure to UV, mask development and curing.

Surface Finish: The metallic copper pads should be shielded from external factors through surface finishing techniques such as Hot Air Solder Levelling (HASL), Organic Solderability (OSP) and Electroless Nickel Immersion Gold (ENIG). The objective of these methods is to apply a film or layer to protect the surface from oxidation.

Solder Masking: A solder mask must be applied on the PCB substrate to separate the conductive pads and insulating surfaces. Liquid photo imageable solder mask is the most common type in which a photoresist mask is used to generate the pattern through exposure to UV, mask development and curing.

Surface Finish: The metallic copper pads should be shielded from external factors through surface finishing techniques such as Hot Air Solder Levelling (HASL), Organic Solderability (OSP) and Electroless Nickel Immersion Gold (ENIG). The objective of these methods is to apply a film or layer to protect the surface from oxidation.

A lot of brand owners of OEMs are outsourcing their products from electronics manufacturing services providers, that is mainly because they can get their electronics made quickly at high quality and competitive price, they do not need to invest in equipment or personnel to build their electronic manufacturing facility. Then they can focus on the design and sales aspects to achieve great success of their brand. Here we will discuss the benefits of outsourcing electronics manufacturing services in detail.

If you outsource the product, the electronic manufacturers will offer you a one-stop service. including PCB fabrication, PCB assembly, electromechanical assembly, testing and inspections, or even electronic design, packaging and distribution. They handle all the steps for you, especially for some difficulties during the process. You don’t need to worry about anything about products. Outsourcing electronic manufacturing services to professional large companies that have qualified production standards can reduce risks in the production process.

Cost-Efficiency

For small and medium-sized companies, purchasing electronic devices and technology costs a lot and it can be avoided. Additionally, it also costs if you need to hire people to work. And you also need the space to place your equipment. But the above problems can be solved if you outsource electronics manufacturing services. Therefore, outsourcing services can help you with cost control and management.

Overall Quality Control

For small and medium-sized companies, purchasing electronic devices and technology costs a lot and it can be avoided. Additionally, it also costs if you need to hire people to work. And you also need the space to place your equipment. But the above problems can be solved if you outsource electronics manufacturing services. Therefore, outsourcing services can help you with cost control and management.

Engineering Support

For small and medium-sized companies, purchasing electronic devices and technology costs a lot and it can be avoided. Additionally, it also costs if you need to hire people to work. And you also need the space to place your equipment. But the above problems can be solved if you outsource electronics manufacturing services. Therefore, outsourcing services can help you with cost control and management.

Cost-Efficiency

For small and medium-sized companies, purchasing electronic devices and technology costs a lot and it can be avoided. Additionally, it also costs if you need to hire people to work. And you also need the space to place your equipment. But the above problems can be solved if you outsource electronics manufacturing services. Therefore, outsourcing services can help you with cost control and management.

Choosing the best partner for your electronics manufacturing needs is paramount in meeting your business goals. A trustworthy partner will be your foundation stone on the road to success. Below are the points why PCBA23 can be your best electronics manufacturing services provider.