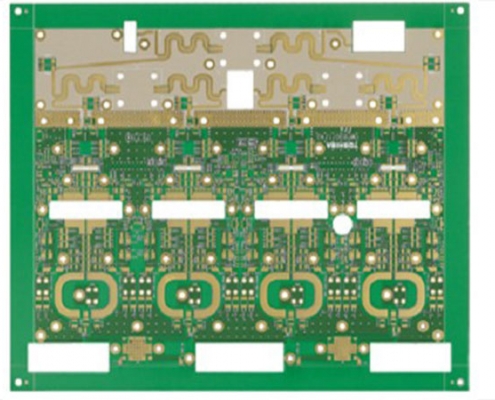

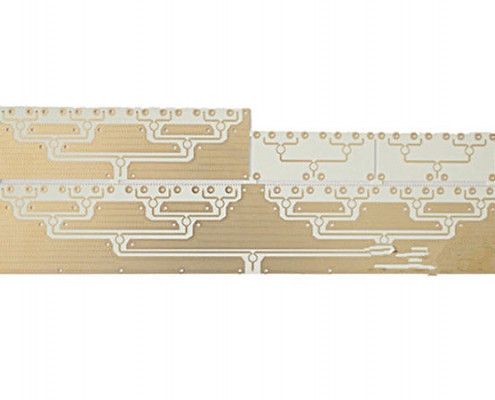

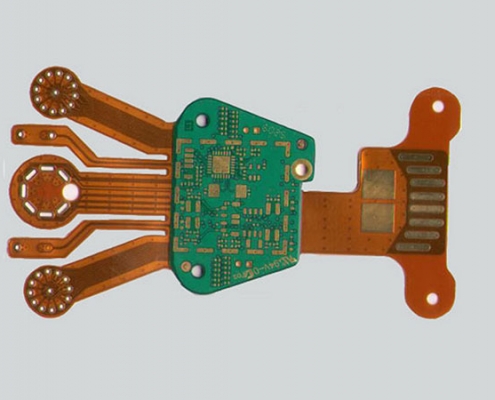

PCBs (printed circuit boards) have, more or less, become a very vital part of modern electronic equipment. In fact, if you were to disintegrate any electronic equipment in your house, the chances are that you are going to come face to face with one of myriad types of PCBs. A basic printed circuit board is comprised of a very large number of passive and active components. They are connected from side to side with traces on the board. It is wholly possible to develop very large circuits on small printed circuits boards with the availability of very small sized electronic components.

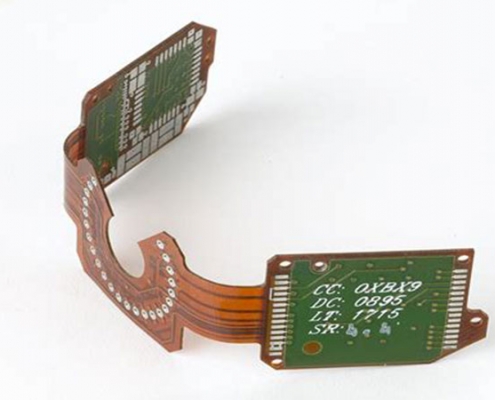

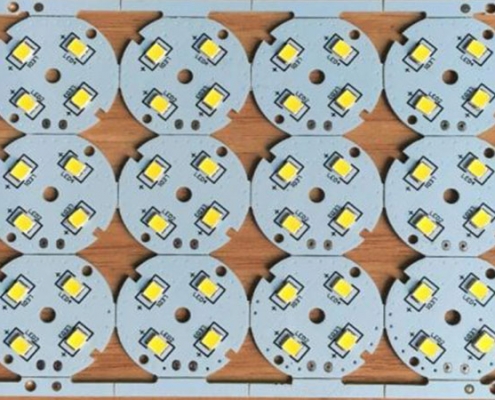

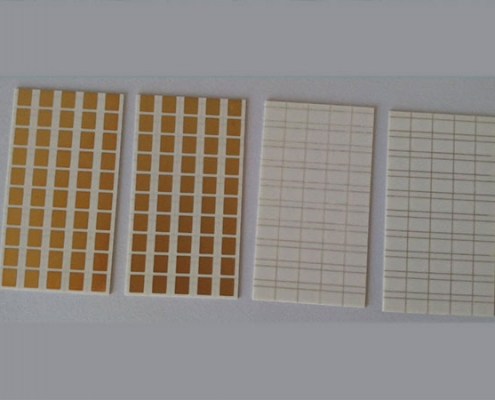

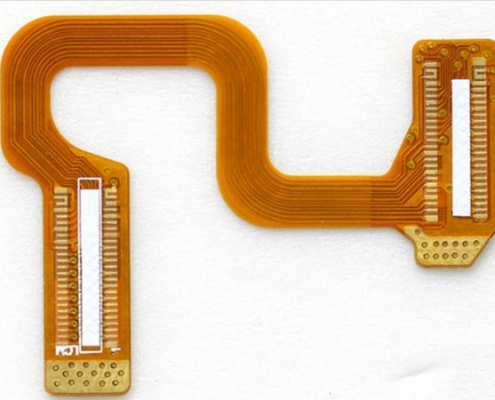

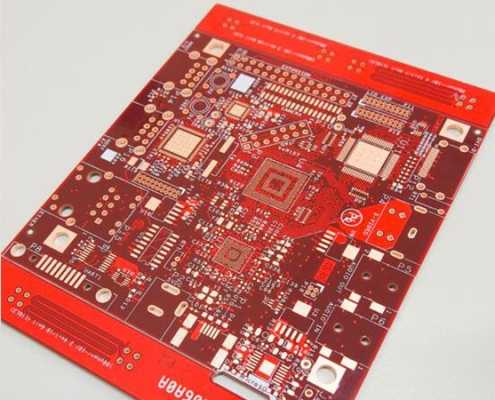

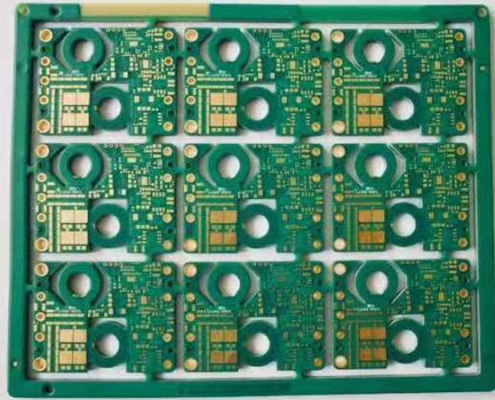

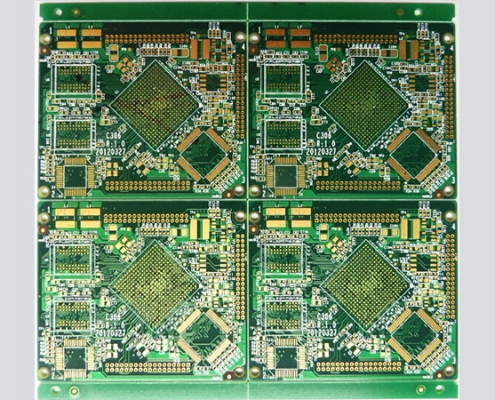

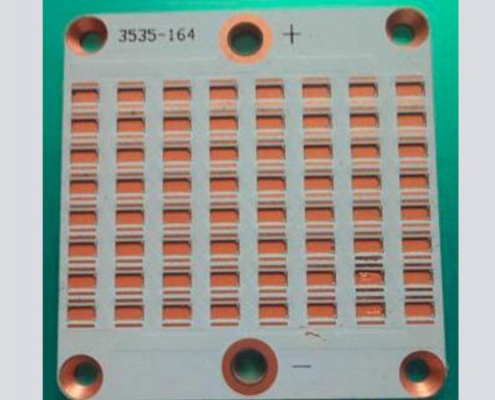

PCBA123 is a professional PCB board manufacturer & supplier in China, supplies durable quality PCB boards for electronic equipment production at competitive price, our products contain custom PCB board service, rigid PCB board, flex PCB board and multi layer PCB board, etc. If you have demands in PCB boards, please don’t hesitate to contact us for more details.

But that is not all PCBs are good for printed circuit boards offer varied advantages which make them the perfect choice for the manufacturers of electronic components, instruments and equipment everywhere.

Advantages of PCB Boards

Compact formaat

A characteristic PCB includes a large number of electronic components. Most of these components are very small in size. It would be close to impossible to connect these components together with wires without the aid of printed circuit boards. A typical printed circuit board offers a simple platform to align the electronic components in a compressed and efficient way. This compactness allows creation of big and complicated electronic circuits in small form factors. This, in turn, takes less space in devices.

Ease in Repair and Diagnostic

One great thing about printed circuit boards is that they are helpful in performing diagnostics for a number of reasons. The electronic components and their polarities on a properly designed printed circuit boards are evidently labeled on the board. This allows convenience during the installation process as well as repair process. Signal paths are often traced during diagnostics. Doing this would be wholly difficult to perform if the traces were not clear to the view and well organized.

Immune to Movement

Another worthwhile thing to notice is that all the components on a PCB are held fixed to the board. Because of this, the electronic circuit (that move or shake) can be placed in devices without worrying about the possibility of displacement of the electronic components and any subsequent electronic short circuits.

Low Electronic Noise

A printed circuit board (that has been properly laid out) lessens electronics noise. If it is not laid out properly then the noise could significantly degrade performance. The electrical components on a printed circuit board are organized in a way that the path lengths of the electrical current between them are lessens. This leads to low radiation and pickup of electromagnetic waves, thus ensuring lower cross talk in between components and in between varied traces, which usually is a major concern in electronic circuits.

Points to Consider before Buying PCB Boards

A key step after you finish your PCB design and have tested it to make sure it works is to secure the parts to go beyond a prototype and into the development of an actual product. While that might seem as simple as doing a Google search for a PCB manufacturer, there are a few things you need to consider before selecting a distributor or manufacturer.

Minimum Orders

Obtaining a few odd parts for your prototype was pretty easy. Getting a few thousand to let you roll into production would be easy as well. What’s much more difficult is getting enough parts from PCB board suppliers to let you continue to test and refine without making a massive commitment in parts orders to a prototype that might not wear well in mass production. Make sure that you search for PCB suppliers that will allow you to buy a lower amount of PCBs for a reasonable cost. Look for a supplier that is familiar with and willing to pool parts orders to save you money and avoid any mandatory minimums.

Verity RoHS Compliance

The guidelines in the Restriction of Hazardous Substances (RoHS) exists to make sure manufactured parts do not pose a threat to consumers. Have your product tested to make sure it adheres to these rules. Not only will it give you greater peace of mind in your product, having the certification will protect you legally if there is a hidden flaw or if your product is misused by consumers and the misuse results in injury.

It also will ensure your product can be sold beyond your immediate country. Some PCBs are illegal in certain countries because of Radio-Frequency Interference (RFI) or Electromagnetic Interference (EMI.) Ensuring your prototype components are compliant for sale in other countries will let you expand if your product is a success.

Assess the Prototypes Potential

Assume your prototype can be mass produced and you have a PCB manufacturing agreement in place. What happens if the success of your product exceeds the manufacturer’s capacity for production? You never want to put the “cart before the horse”, but you have to plan on success, which means ensuring your PCB and PCB component manufacturers can handle large orders with ease. You do not want to have to find a new manufacturer as soon as your product becomes a hot item.