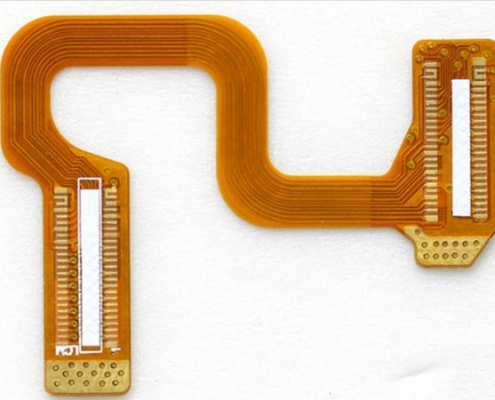

Flex PCB consists of metallic layer of traces, boned on the non-conductive layer, with flexible feature, can be modified or folded to any other shape according to the real space. PCBA123 is a professional flex PCB board manufacturer, supplies quality flex PCB board for electronic equipment, with excellent anti-corrosion, factory price, quality assurance.

Flex PCB boards or Flexible PCB boards are simply abbreviated as FPCs. Unlike ordinary hard resin circuit boards, you can rely on them for a number of reasons including high flexibility, less wiring space limitations, and density.

What Is Flexible PCB Board?

A flexible PCB board is designed to provide flexibility when it comes to designing an electronic product. There is a lot that you can do with it. Even if you are struggling to create something, you can count on it to help you out.

Advantages and Disadvantages of Flexible PCB Board

- Lower Weight

A great thing about a flexible PCB board is that it weighs less. Despite using more parts, it is designed to weigh less. It also uses less wiring to make sure that users have no trouble designing anything they want. You can use the flexible PCB board for creating just about everything.

- Less Wiring

Another amazing benefit of a flexible PCB board is that it requires less wiring. This means that you do would not to worry about dealing with any as many connections. You will find it to be simple enough for ensuring flexibility. It performs well under a variety of conditions.

- Costs Less

In addition to the above, the best thing about a flexible PCB board is that it costs less. This means that you can also benefit from massive savings when you opt for a flexible PCB board. If you are on a strict budget and want to ensure that you have no trouble producing a batch of electronic products, a flexible PCB board is just what you need to make it a reality.

- Not Suitable for Every Situation

Even though a flexible PCB board is designed to offer flexibility, it is not the most flexible option out there. This means that you cannot expect to use in just about every situation. You need to think ahead if you want to put it to good use.

Applications and Usages of Flexible PCB Board

When it comes to applications and usage, flexible PCB boards do not disappoint. You can use them for just about everything including the following.

- Automotive

- Medical

- Aerospace

- Industrial Electronics and Automation

Why You Should Use Flex Circuits in Your Application

Considering using a flexible printed circuit board (flex PCB) in your next project? Flex circuits offer several advantages, whether you plan to use them in a future project or for revamping your existing designs. Here we detail some of the most impactful advantages of flex PCB, including packaging, reliability, capabilities, and cost savings.

Flexible Circuit Packaging Freedom

Flex circuit boards can be made to fit where other solutions aren’t viable. You can save even more space by replacing a wired assembly with a flex circuit. Flex also offers an increase in tighter bend capabilities. Because of its ability to more efficiently occupy space, there may even be opportunities to replace multiple circuit boards, connectors, etc. with a single rigid-flex unit.

Reliability of Flexible Printed Circuits

When it comes to reliability, flex and rigid-flex PCB’s?have you covered. Flex can reduce the overall number of interconnects required, which in turn means fewer solder joints, connectors, and contact crimps. With fewer interconnects there will be fewer potential sources of failure resulting in improved reliability. Additionally, the weight reduction and flexibility of the circuit improves vibration and shock performance.

Flex PCB Capabilities

Flex material properties perform very well in high speed controlled impedance designs. As far as component/connector assembly is concerned, flex circuits accept any component or connector that can be assembled to a rigid PCB. Additional options available include ZIF connectors, crimped contacts, and direct solder.

Flexible circuits also perform well in harsh environments. Extreme temperature applications can run up to 200°+ Celsius and flex provides better heat dissipation than rigid printed circuit boards. Flexible circuit?boards?also have excellent resistance to chemical, radiation, and UV exposure.

Cost Savings Benefits

Performance benefits aside, factoring the savings benefits alone make flexible circuit boards worth the investment. Using flexible PCB reduces the overall finished assembly packaging and material requirements, creating lower cost shipments. Replacing multiple components lowers assembly costs due to fewer parts and simplified installation. Increased reliable of flex PCBs creates longer lasting products, again saving you from having to spend more on reorders.

How to Find a Reliable Flexible PCB Board Manufacturer in China?

To make sure that you pick out the right company for the job, you need to consider the following tips.

- Ask the company for a few references.

- Look into the reputation of the company to determine if it takes its reputation seriously.

- View the import and export license.

- Inspect the business license of the company.

- Check the quality control system certificate to ensure that it is valid.

Choose the Best Flexible PCB Board Manufacturer in China

PCBA123 is the ultimate company for manufacturing flexible PCB boards in China. You can turn to it whenever you require a flexible PCB board. It is here to provide you everything that you need and more. Feel free to reach out if you have any queries.