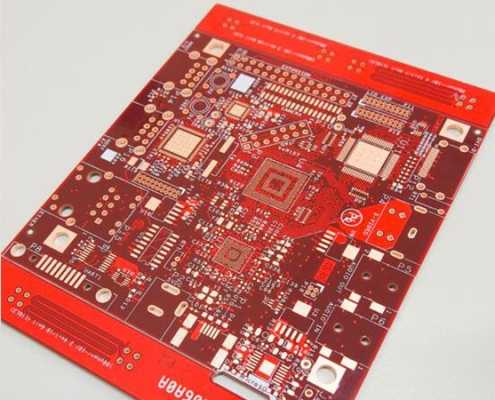

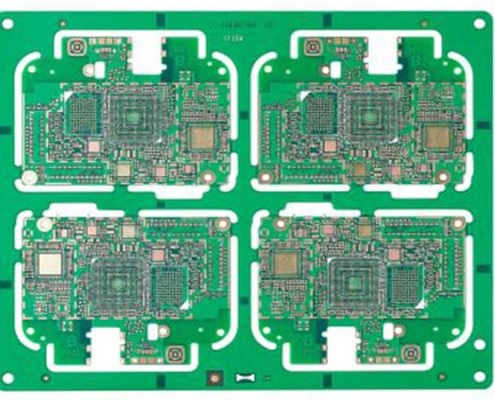

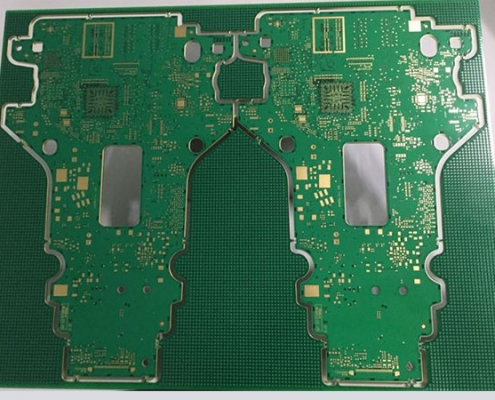

High density inter-connector HDI PCB board has higher wiring density per unit area than conventional board, with finer space and lines, minor vias and capture pads and higher connection pad density, can enhance electrical performance, reduce the weight and size of equipment. Thus, the HDI PCB is usually applied in complex electronic devices that requires excellent performance and small volume, such as mobile phones, cellular phones, touch-screen devices, laptop computers, digital cameras, 4G and 5G network communications, even military applications.

Wireless networks and satellite communications have changed the world we live in. They have led to the emergency of high-speed and high-frequency information production. As data, video, and voice has been standardized for high speed transmission and large capacity, there is a need for high-frequency products. This is where HDI PCB boards come into place.

What Is HDI PCB Board?

HDI PCB boards are defined as micro boards that feature a hole that has a diameter of 6 mils. As there is minimum contact density, the wiring density makes up for it. HDI PCB boards are necessary for streamlining communications and powering the future. There is no better PCB board out there. Hence, chances are that you have used an HDI PCB board.

Advantages and Disadvantages of HDI PCB Board

There are various advantages of HDI PCB boards as mentioned below.

- Cut down PCB Cost: One of the main benefits of HDI PCB boards is that they help reduce PCB cost. As the density of the PCB is increased, there is no need for complicated press-forming processes. This helps reduce costs.

- Increase Line Density: Another great thing about HDI PCB boards is that they help increase line density. The interconnection between traditional circuit boards and conductors through the lines ensures that only the right amount of space is occupied so that the micro-hole technology can improve interconnection.

- Conductive to Advanced Packaging Technology: When it comes to mechanical drilling and traditional drilling technology, HDI PCB boards are a class apart. They allow you to utilize the latest package technologies like DCA, CSP, and Array package.

- Provide Better Signal Correctness and Electrical Performance: Signal reflection is reduced by the micro-hole interconnection. As the physical structure tends to be short and small, the effect of capacitance and inductance is reduced.

- Greater Reliability: With HDI PCB Boards, you get to benefit from better reliability when it comes to transmitting signals.

- Improved Thermal Properties: HDI boards use insulating dielectric material for better thermal properties.

- Expensive: If there is one con of HDI PCB boards, it is that they can be quite expensive. But, they make up for it in the form of savings.

Applications and Usages of HDI PCB Board

There are various uses of HDI PCB boards as mentioned below.

- Smartphones

- Digital Cameras

- MP4

- Computers

- Automotive Electronics

- Other Types of Digital Products

How to Find a Reliable HDI PCB Board Manufacturer in China?

To find a reliable HDI PCB board manufacturer in China, you must follow the tips mentioned below.

- Look into the quality control system certificate of the company for ensuring validity.

- Review the import and export license.

- Research company reputation.

Choose the Best HDI PCB Board Manufacturer in China

As you know everything about HDI PCB boards, you must find the best manufacturer in China. PCBA123 is just the company that you need to consider ordering from. It has been in the industry for a very long time and knows how to deliver outstanding HDI PCB boards that last a long time.